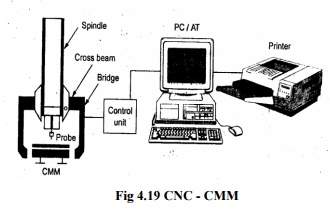

CNC-CMM

Construction

The main features of CNC-CMM are shown in figure has stationary granite measuring table, Length measuring system. Air bearings; control unit and software are the important parts of CNC & CMM.

· Stationary granite measuring table

Granite table provides a stable reference plane for locating parts to be measured. It is provided with a grid of threaded holes defining clamping locations and facilitating part mounting. As the table has a high load carrying capacity and is accessible from three sides. It can be easily integrated into the material flow system of CIM.

· Length measuring system

A 3- axis CMM is provided with digital incremental length measuring system for

each axis.

· Air Bearing

The Bridge cross beam and spindle of the CMM are supported on air bearings.

· Control unit

The control unit allows manual measurement and programme. It is a

microprocessor control.

· Software

The CMM, the computer and the software represent one system; the efficiency

and cost effectiveness depend on the software.

Features of CMM Software

(i) Measurement of diameter, center distance, length.

(ii) Measurement of plane and spatial carvers.

(iii) Minimum CNC programme.

(iv)Data communications.

(v) Digital input and output command.

(vi) Programme for the measurement of spur

(vii)Interface to CAD software.

A new software for reverse engineering complex shaped objects. The component is digitized using CNC CMM. The digitized data is converted into a computer model which is the true surface of the component. Recent advances include the automatic work part alignment and to orient the coordinate system. Savings in inspection time by using CMM is 5 to 10% compared to manual inspection method.