Rotary Pumps

The rotary pump is good for handling viscous liquids, nut because of the close tolerances needed, it can not be manufactured large enough to compete with centrifugal pumps for coping with very high flow rates.

Rotary pumps are available in a variety of configurations.

• Double lobe pump

• Trible lobe pumps

• Gear pump

• Gear Pumps

• Spur Gear or Extern al-gear pump

External-gear pump (called as gear pump) consists essentially of two intermeshing gears which are identical and which are surrounded by a closely fitting casing. One of the gears is driven directly by the prime mover while the other is allowed to rotate freely. The fluid enters the spaces between the teeth and the casing and moves with the teeth along the outer periphery until it reaches the outlet where it is expelled from the pump.

External-gear p umps are used for flow rates up to about 400 m3/hr working against pressures as high as 170 atm. The volumetric efficiency of gear pumps is in the order of 96 percen t at pressures of about 40 atm but decreases a s the pressure rises.

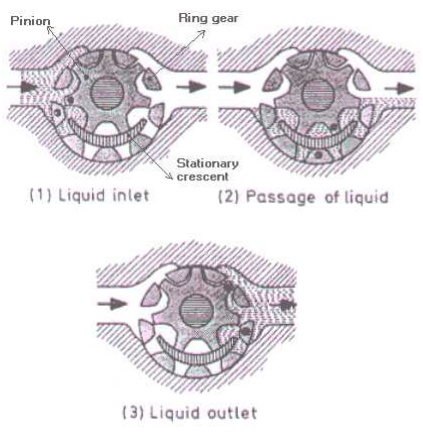

Internal-gear Pump

The above figure shows the operation of a internal gear pump. In the internal-gear pump a spur gear, or pinion, meshes with a ring gear with internal teeth. Both gears are inside the casing. The ring gear is coaxial with the inside of the casing, but the pinion, which is externally driven, is mounted eccentrically with respect to the center of the casing. A stationary metal crescent fills the space between the two gears. Liquid is carried from inlet to discharge by both gears, in the spaces between the gear teeth and the crescent.